LNG (LBG) production process can be modelled and simulated through software for chemical systems design as well as by means of ad hoc routines.

The achievement of the specific objective is structured according to the following steps:

• identification and formulation of the model: modeling of the LNG (LBG) process and application of economic functions to the model for detailed analysis of costs and performances as well as for comparison with other technologies.

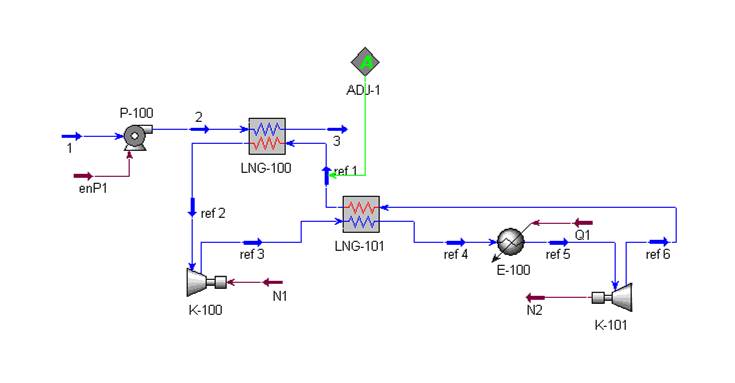

The process flow diagram, from the battery limit of the natural gas (biogas) pipeline to the final product, includes the following units:

– cleaning of natural gas (biogas) to remove non-CO2 undesired compounds (water, siloxanes for biogas, …);

– CO2 removal, where the unusual low temperature of biomethane advices the use of cryogenic technologies, for instance cryogenic distillation and further finishing separation by anti-sublimation;

• optimization of the performances: the model will be optimized according to objective functions taking into account costs, environmental impact, efficiency.

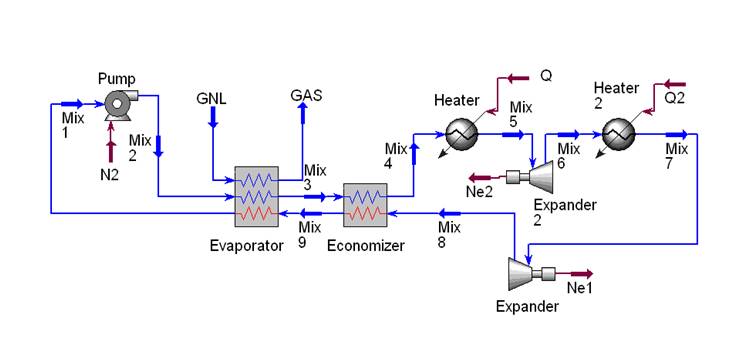

When considering the LNG supply chain also the LNG regasification process with the “cold” recovery has been considered.

Rankine cycle with double expansion for LNG regasification

Brayton cycle with methane for LNG regasification

Back to Research.