The continued development of bioeconomy is expected to deeply transform several segments of the chemical industry, from bulk to fine chemistry. In this field, in which the separation costs come to exceed 70% of the total production costs, the GASP group has recently oriented his research activity towards two strategic areas.

Downstream dicarboxylic acid purification

In the production of green dicarboxylic acids by fermentation the downstream separation processes is required due to the many impurities in the fermentation broth such as by-produced acids, carbon sources and salts. GASP, thanks to the deep knowledge on unit operations, is studying efficient process solutions for green acids purification in order to achieve high purity and to reduce costs.

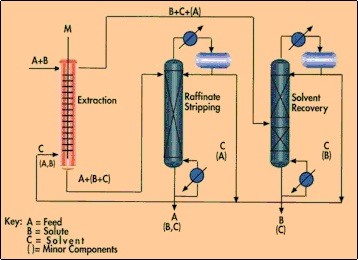

Transferring the skills on amine treating acquired in the framework of natural gas upgrading, GASP is developing a new process for purification of succinic acid by reactive extraction with TOA, which is expected to be more convenient and more environmentally friendly than conventional separation processes.

Sugars purification

Second generation sugars will be the platform for many green chemicals, eliminating the problem of food-feed competition. However this non-food based feedstock is characterized by a more complex matrix which requires higher purification effort, in order to make feasible catalytic processes and increase cell culture titers.

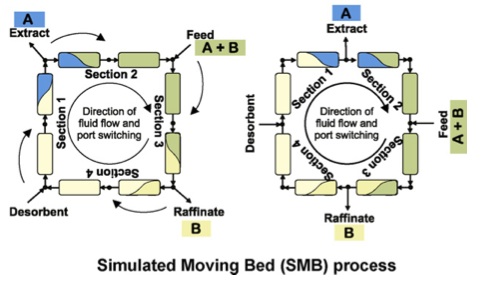

Our research activity is therefore focused on identification of process solutions for low-cost purification of ligno-cellulosic derived sugar streams, aimed at the production of green chemical commodities. In particular, the GASP group studies the applications of continuous chromatographic processes to the separations involved in 2nd generation biorefinery, by modeling and optimizing existing technologies and developing ad hoc solutions for this new field.

Back to Research.