Hydrogen produced by water electrolysis powered by electricity from renewables is seen as a carrier capable of storing renewable energy, limiting the disadvantages due to their fluctuating nature.

The most cost-competitive renewable electricity hubs, for example the wind farms of the North Sea or solar parks of the Middle East, are thousands of kilometres away from the large productive sites in Europe. Therefore, storage and supply chain infrastructures need to be developed to move hydrogen through long distances.

The main obstacle to gaseous hydrogen large-scale delivery is its low volumetric density, which would lead to excessive dimensions of the storage and transport equipment. In order to increase the volumetric density, the following transformations are considered: liquefaction, chemical storage in ammonia or in liquid organic compounds.

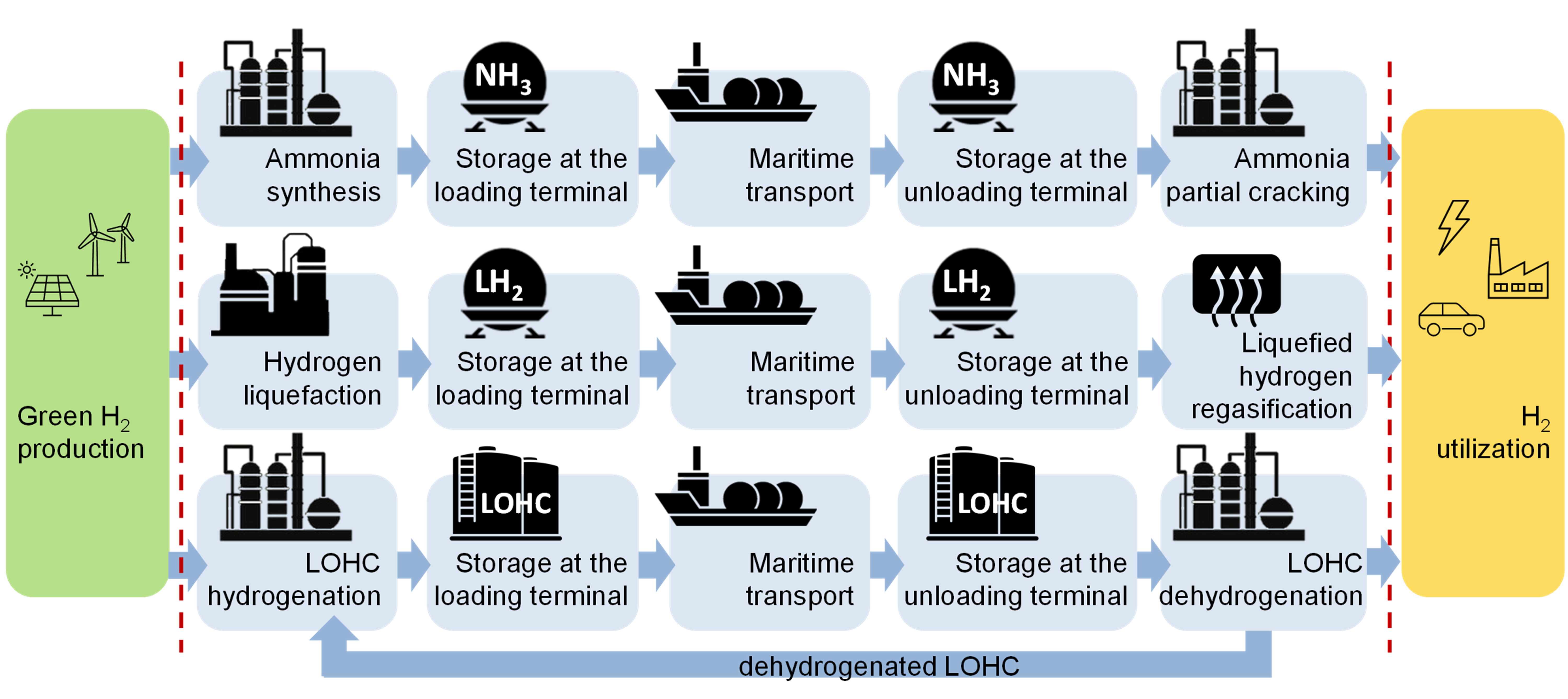

Thus, three value chains are being studied: the first one includes liquefaction, transport and regasification, the second one ammonia synthesis, transport and ammonia cracking, the third one hydrogenation of an organic compound, transport and dehydrogenation.

Along the different value chains, the most energy consuming processes must be optimized. After that, a techno-economic analysis drives the choice to the best option to develop a hydrogen supply chain.

Back to Research.